Our product range

Click on the products below and discover our full range.

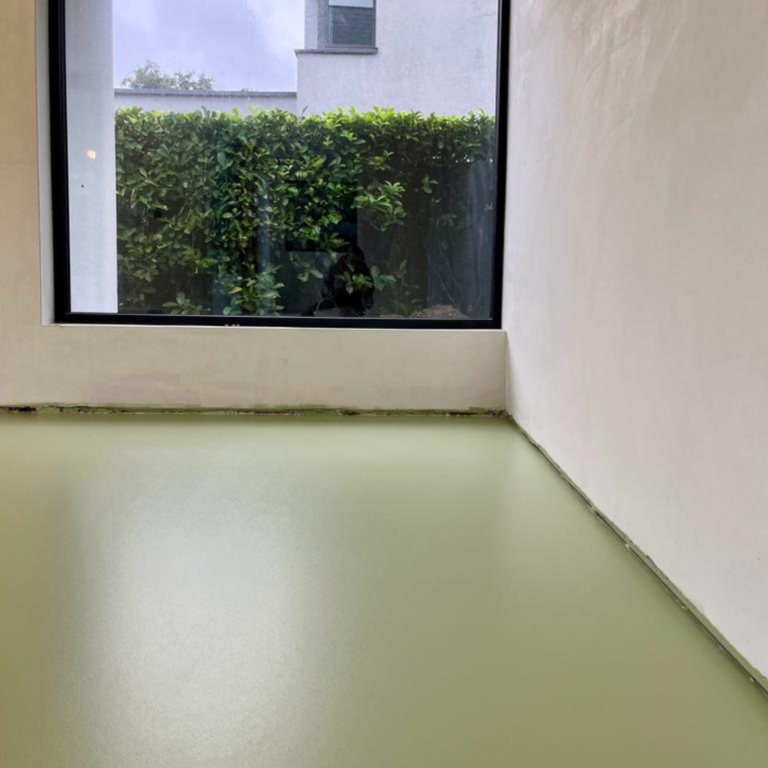

Polyurethane floor system

This flooring system is a Polyurethane cast floor, also called a PU cast floor.

You obtain a one-color floor after installation, completely seamless and jointless finish.

The benefits

This polyurethane floor is...

- easy to repair.

- available in different colors and you can reorder without problems with the tono or color tones.

- suitable for use with underfloor heating.

- liquid and waterproof.

- easy to maintain.

- elastic and does not tear.

- If necessary, we install an additional soundproofing layer.

- resistant to acids & bases.

- It can last a lifetime, but it all depends on how you use your screed.

- Easy to combine with a mat frame.

The placement

The placement consists of 5 tiers and takes about a week. You must wait 5 days for the full chemical curing of the Polyurethane floor. During these days, the keep floor dust free and may not walk this one.

These layers consist of a primer, a leveling layer, the polyurethane flooring system and then the 2 colored top or painting coats.

Do you have specific questions about the installation of these PU cast floors? Then ask them through our contact form!

Wall System

This wall system allows you to walls seamless and jointless be finished.

This can be fully integrated into your existing screed, in the same color or not.

This wall system consists of watertight plates which we glue to a dry and level lower wall. Over this we then place the material of the screed.

The benefits

- Perfect combinable with a polyurethane walk-in shower;

- Low maintenance;

- Moistureproof - so this is also suitable for shower walls;

- 100% waterproof - you don't need waterproofing layers or orange cloths;

- The same color as your screed is possible.

- Possibility of installing shelves, seats, etc. in bathroom or shower.

- Only 6 mm thickness - including bonding and plates.

The placement

We glue a plate of 3 mm thickness against the walls to ensure a solid and flat surface. Thanks to the waterproof nature of these boards, we can also use them in bathrooms.

We glue the plates completely seamless against the wall. After this, we apply 2 coats of polyurethane paint to the walls.

When you want the shower installed in this material, we provide full integration of a bench, planks, the gutter, etc. As a result, you obtain a beautiful seamless bathroom, shower or room.

Stair system

This system ensures that you have your concrete stairs can also be fully incorporated into the screed.

You get a seamless staircase In a color of your choice.

The benefits

What are the benefits of a stair system?

- Tight view;

- Completely seamless;

- Fully along ge integrated into your cast floor;

- Available in most RAL and NCS colors.

The placement

We ensure that the entire concrete staircase is the right size and completely level. If necessary, we place a zettrap. After this, we work in a similar way to an ordinary PU screed. We bring 5 tiers to where the last 2 layers are the layers of painting or coloring are.

Microtopping

Our microtopping is a very strong floor system on epoxy base.

Thanks to the flame pattern create a country feel.

Our microtopping is stronger than cement-based variants such as mortex, as our product is produced from epoxy. It also contains no chemicals which makes it safer for people, environment and surroundings.

The benefits

What are the benefits of epoxy flooring/microtopping?

- Available in lots of different colors;

- Waterproof;

- Resistant to harsh substances such as acids and chemicals;

- Impact and shock resistant;

- Very strong;

- Easy to clean and maintain.

The placement

We place the microtopping only by hand using a spatula. Similarly, we make the pattern with flames in your floors or walls.

This system consists of 5 tiers and can be placed on any dry, level and solid surface. We always place this system indoors, never outside due to weather conditions.

Equalin

What is Equalization?

Are you renovating and decide to break out your old tiles? Equalization comes in handy when your old screed is not even or beautiful enough.

Equalization is thus a cement-based leveling layer that you use to make your ground back to level.

The placement

A cement-based leveling layer requires a lot of water, which means you have to use the drying times always have to respect. The substrate must first be well curing before placing our products on top of this.

Only after the substrate is sufficiently dry can you start to renew with, for example, a PU floor or microtopping.

Flakes floor

A flake floor is a screed, but this can be compared in terms of appearance to a terrazzo floor. We place these seamless and jointless. You can also choose the colors of the screed and the flakes/flakes.

Through this website put together your own special flakes screed: https://floorconfigurator.com/. You decide on the color of the screed, the colored flakes and the busyness of the pattern.

The benefits

What are the benefits of a Flakes floor?

- Personal color choice;

- View of a terrazzo tile;

- Easy maintenance;

- Suitable for floor use only;

- All advantages of a cast floor: strong, seamless & jointless, scratch-resistant, etc.

The placement

We first provide the screed in your chosen color. Then we sprinkle the flakes. They fall lightly on the floor and do not sink in. We install this screed in the same way as a normal Polyurethane floor.

Concrete look

What is concrete look?

A concrete look is a screed where we combine 2 colors. With a regular PU cast floor we use 1 color, but with this variant we make it possible to combine 2 colors.

The placement

We mix these carefully in a tub which allows us to 1 mixture with a light and dark shade get. After this, we apply the mixture to the floor. Then by spreading it out further we bring in more or less drawing. The more drawing, the busier the flame.